The PVC Imitation Marble Profile Production Line

The PVC marble with the advantages of environmental protection, light in weight, easy maintenance, no radiation, economic is now widely used in commercial. The PVC Marble Profile is accessories which work together with Marble sheet.

The Benefit of PVC Marble sheet and profile:

* Available in different design and color, realistic nature marble looks

* The surface is smooth and the mirror highlight effect is obvious.

* The paint film is plump and the color is plump and attractive.

* None fading, long-lasting color, not easy to change color under sunlight, and solve the phenomenon of chromatic aberration.

* Supreme durability makes it a good option for high-traffic areas or homes.

* Scratch resistance, Water resistance, high hardness, the brighter it is when worn, and it will not deform for a long time as it is cured at room temperature.

* Zero formaldehyde, without any glue during all production.

* Can be installed over radiant heating system

* Easy to install, clean and maintain

* Cost effective and eco-friendly.

The PVC marble sheet and profile is a kind of new material which is widely used for ceiling, wall panel, background wall, door of kitchen, commercial and residential place. It is 100% water proof, rigid surfaced, non flammable and nontoxic material.

it stands for a couple of terms that are used interchangeably: stone plastic composite or stone polymer composite.

it refers to the make-up of the core, and the SPC core is what makes this marble sheet and profile so incredibly durable, maintaining its form even over uneven subfloors.

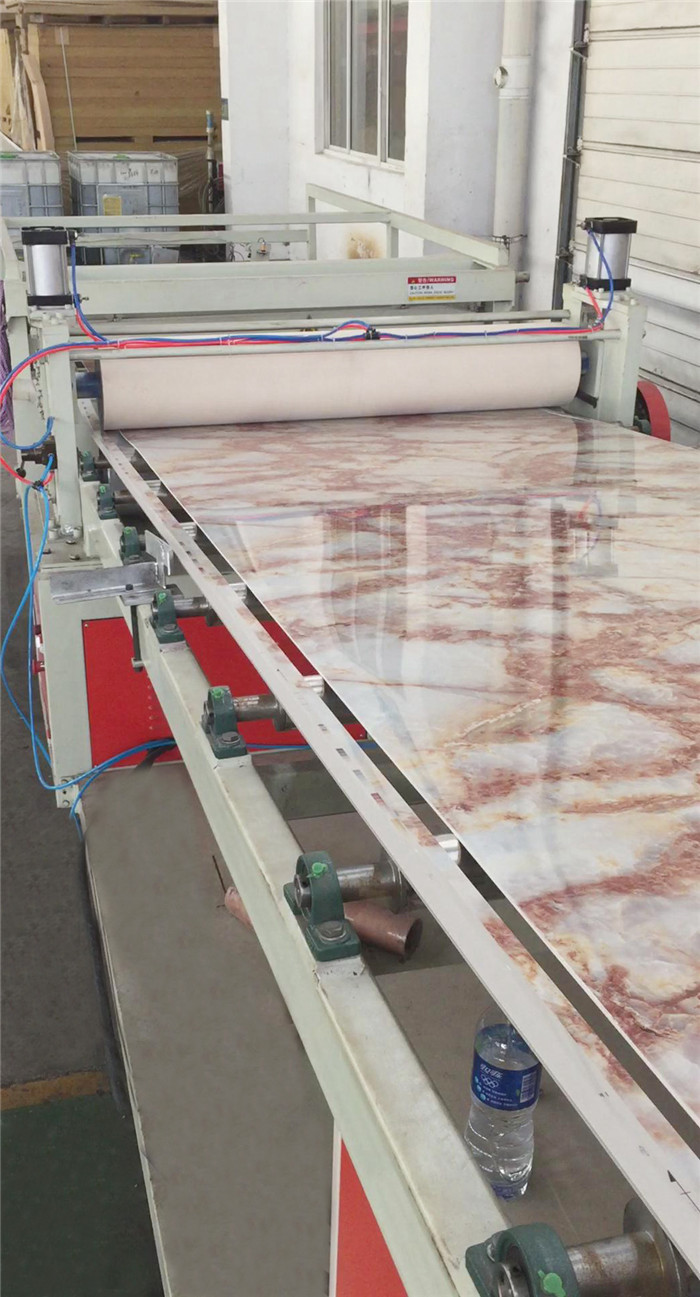

The PVC marble profile consists of PVC profile core and decorating film, by the process of heat transfer for form the composited stone plastic sheet.

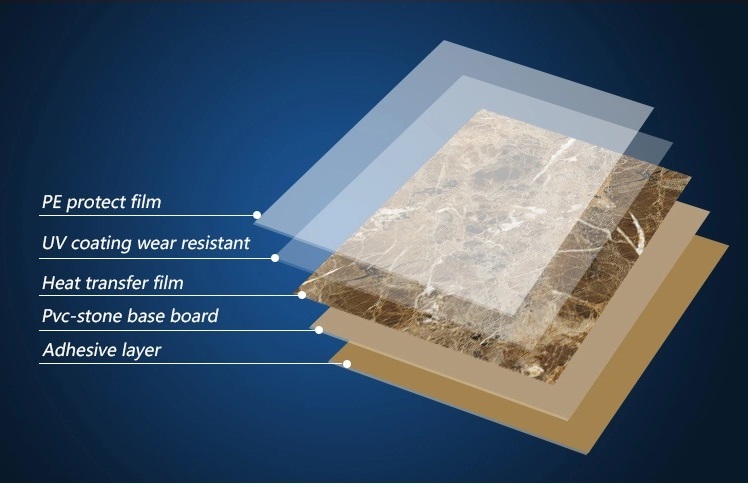

the composited PVC marble profile has multiple layer, include UV coating layer, color layer, stone plastic layer and base core.

Compare with real stone marble profile, this PVC marble profile is also wear resistance, stain resistance, dimension distrotion resistance, but more economic!

Machine Specification & Technical Data

The Process Flow:

Mixer - Spiral loader- Twin screw extruder-Mould-Roller calender - Cooling group rollers - Hual off -Transversal cutter- Edge cutter-Conveyor-UV treatment.

*With the powerful twin screw plastic extruder machine, the high plasticzation capacity of mixing material, guarantee the uniformity of plastic melting and color.

*Precision adjusting of the thickness of sheet by high quality clothes rack type mould head.

*The ±1℃ precision temperature control for the plasticization process, thickness and smooth surface.

* More selection for choice of roller arrangment which could be Vertical, Horizontal or Free adjusting.

* Both way controll for the thickness of sheet accurately by adjusting screw or oil pressure.

*Double loop cooling and mould temperature controller are adopted.

*Thickness of marble sheet can be controlled accurately by different kind of way.

*Precision cutting machine for giving stable and accurate cutting of length.

*High glossy UV varnish coating.

Main Technical Parameters

| Model No. |

Motor Power (KW) |

Suitable Material |

Product Width(mm) |

Production turnover (KGS/hour) |

| PVCMBP-C55 |

22 |

PVC+CaCO3 |

150 |

150 |

| PVCMBP-C65 |

37 |

PVC+CaCO3 |

300 |

250 |

PVC Imitation Marble Sheet Product Layer

| First Layer | PE PROTECT FILM |

| Second Layer | UV coating wear resistant |

| Third Layer | Heat transfer film |

| Fourth Layer | PVC-Stone base board |

| Fifth Layer | Adhesive layer |

The Machine Line

The PVC imitation Marble Profile production line is also called Plastic artificial Marble Stone Panel Profile Production Line/PVC artificial Marble Profile Extrusion line/PVC plastic Marble Profile making line the main unit, plastic extruder, is designed available of Concial Twin Screw plastic extruder with strong powder out.

the Twin Screw Plastic Extruder machine is also the main unit for the production line of producing PVC PIPE , PVC profile and etc.

Our machine line have a high rate of return on investment and can pay for themselves quickly.

As a 20 years experence factory, we can provide customers with comprehensive technical suport and also support from raw material formula, production process to molding equipment.

Application