Good Wholesale Vendors Ceiling Panel Extrusion Line - PVC Wall Ceiling Door Hollow Panel Production Line – Zhongpeng Detail:

The PVC Hollow Panel production line

The PVC Wall / Ceiling / Door Hollow Panel Production line is used to produce those building material from 150mm to 1200mm width different section shape and height.

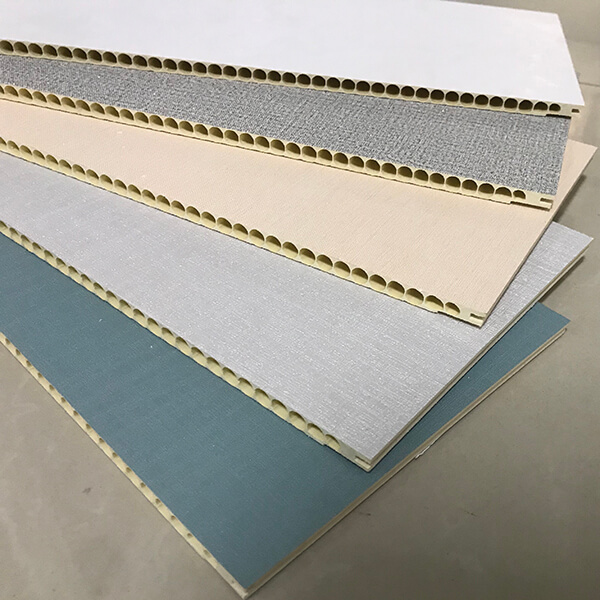

The surface of PVC Hollow Panel can be treated by double color roller printing & coated with UV lacquer or by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

The benefit of PVC, PP, PE hollow Panel.

* The hollow grid plate and feed block can have UV protection on both sides

* The PP and PE hollow grid panels produced by special molds are light in weight, moisture-proof,

* Has high impact strength, good weather resistance and UV resistance

* Available in different design and color, realistic nature wood or marble looks

* Thickness between 4-25mm, some special design can be 36mm. available shape section of H, X and etc.

* Width between 1200-2200mm, can be coated with ultraviolet layer

* Resistant to water, wear, scratch, tear, moisture, termite, insects.

* Zero formaldehyde, without any glue during all production.

* Easy to install, clean and maintain

* Easy to stand on for longer periods of time.

* Cost effective and eco-friendly.

This production line consists of conical twin screw extruder, calibration platform, hauling machine, cutting machine, automatic plate lifting machine/stack rack.

With different mould and corresponding surface treatment equipment, it can produce different kinds of hollow panel

Such as: PVC ceiling panels, PVC wall panels, PVC door panels, PVC furniture panels, PVC cabinet panels, etc.

Machine Specification & Technical Data

*With the powerful twin screw plastic extruder machine, the high plasticzation capacity of mixing material, guarantee the uniformity of plastic melting and color.

*The upper and lower die lips are adjustable, and the production thickness fluctuation can be controlled within 3%

*the built-in heater function provides rapid heating and excellent temperature retention.

*The ±1℃ precision temperature control for the plasticization process, thickness and smooth surface.

*A separate air conditioner can make it easier to control the air volume of each part, thereby improving product quality

*The smoothness of the channel reaches 0.015-0.03um, which ensures anti-stagnation

* More selection for choice of roller arrangment which could be Vertical, Horizontal or Free adjusting.

*Precision cutting machine for giving stable and accurate cutting of length.

*Available high glossy UV varnish coating.

*The cooling vacuum calibrator is made of specially processed materials to ensure maximum wear resistance and no deformation

*Special temperature control waterway and vacuum calibration design allow temperature adjustment to meet various physical performance requirements of different materials

Main Technical Parameters

| Model No. |

Motor Power (KW) |

Suitable Material |

Product Width(mm) |

Production turnover (KGS/hour) |

| PVCWP-C51 |

18.5 |

PVC+CaCO3 |

300 |

120 |

| PVCWP-C55 |

22 |

PVC+CaCO3 |

300 |

150 |

| PVCWP-C65 |

37 |

PVC+CaCO3 |

600 |

250 |

| PVCWP-C80 |

55 |

PVC+CaCO3 |

1200 |

400 |

The regular Panel module:

| Size |

Thickness |

Weight |

| 915mmx1830mm |

14mm |

10kg |

| 915mmx1830mm |

15mm |

12kg |

| 915mmx1830mm |

18mm |

13kg |

| 1220mmx2440mm |

14mm |

18kg |

| 1220mmx2440mm |

15mm |

20kg |

| 1220mmx2440mm |

18mm |

25kg |

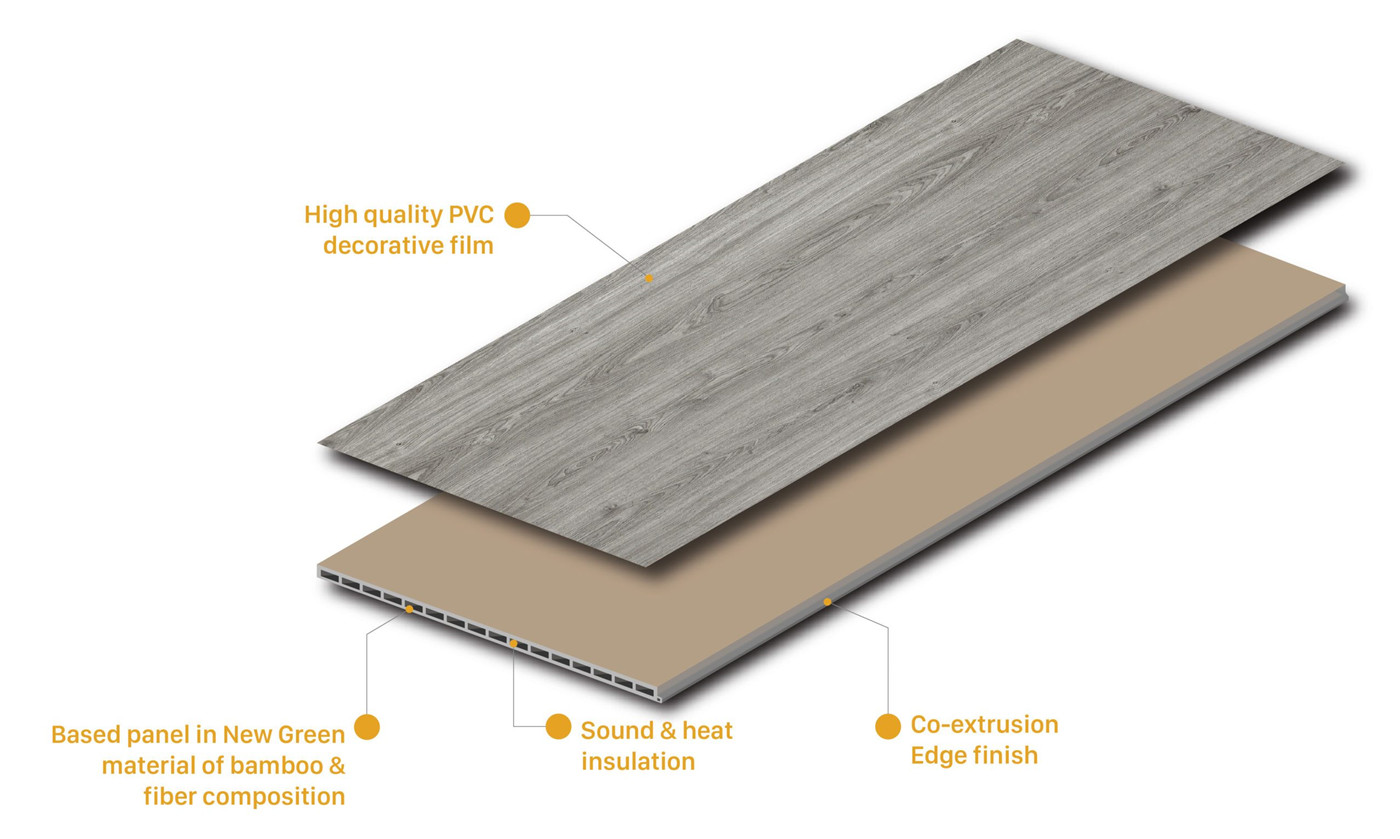

PVC Hollow Panel Sheet Product Layer

| First Layer | High quality PVC decorative film |

| Second Layer | Base Panel |

| Third Layer | Sound and heat insulation |

| Fourth Layer | Co-extrusion edge finish |

The Machine Line

The PVC Wall / Ceiling / Door Hollow panel production line is also called Plastic hollow door board machine Line /PVC Ceiling Panel Decoration Wall Panel Extrusion Line/PVC Door furniture hollow panel extrusion line/ PVC hollow construction board extrusion line/PVC sheet panel board extruder machine line

The main unit, plastic extruder, is designed available of Concial Twin Screw plastic extruder with strong powder out.

The Twin Screw Plastic Extruder machine is also the main unit for the production line of producing PVC PIPE , PVC profile and etc.

Our machine line have a high rate of return on investment and can pay for themselves quickly.

As a 20 years experence factory, we can provide customers with comprehensive technical suport and also support from raw material formula, production process to molding equipment.

Application

Product detail pictures:

Related Product Guide:

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for Good Wholesale Vendors Ceiling Panel Extrusion Line - PVC Wall Ceiling Door Hollow Panel Production Line – Zhongpeng, The product will supply to all over the world, such as: Nepal, Chile, Gambia, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

We are pleased to have your advice personally:

-

High Performance Pipe Extruon Machine - PVC Pi...

-

Factory wholesale Pipe Extrusion Line - PVC Pi...

-

OEM Factory for Imitation Tile Wall Panel Produ...

-

OEM Manufacturer Plastic Marble Stone Decoratio...

-

2020 wholesale price Skinned Foam Board Product...

-

OEM Manufacturer Plastic Marble Stone Decoratio...